An independent food supply was previously an unattainable goal for many governments, cities, regions and institutions. The NaturalFarm competence centre now makes this goal tangible. Take advantage of this centre to make your country or region independent.

The advantages of a NaturalFarm Competence Center lie in the creation of an independent and sustainable food supply. It offers specialized training opportunities, promotes local agricultural production, and enables the development of resilient infrastructure. This reduces reliance on external supply chains, creates jobs, and strengthens the regional economy. Additionally, it contributes to sustainable development by introducing innovative agricultural methods and technologies.

NaturalFarm Competence Center

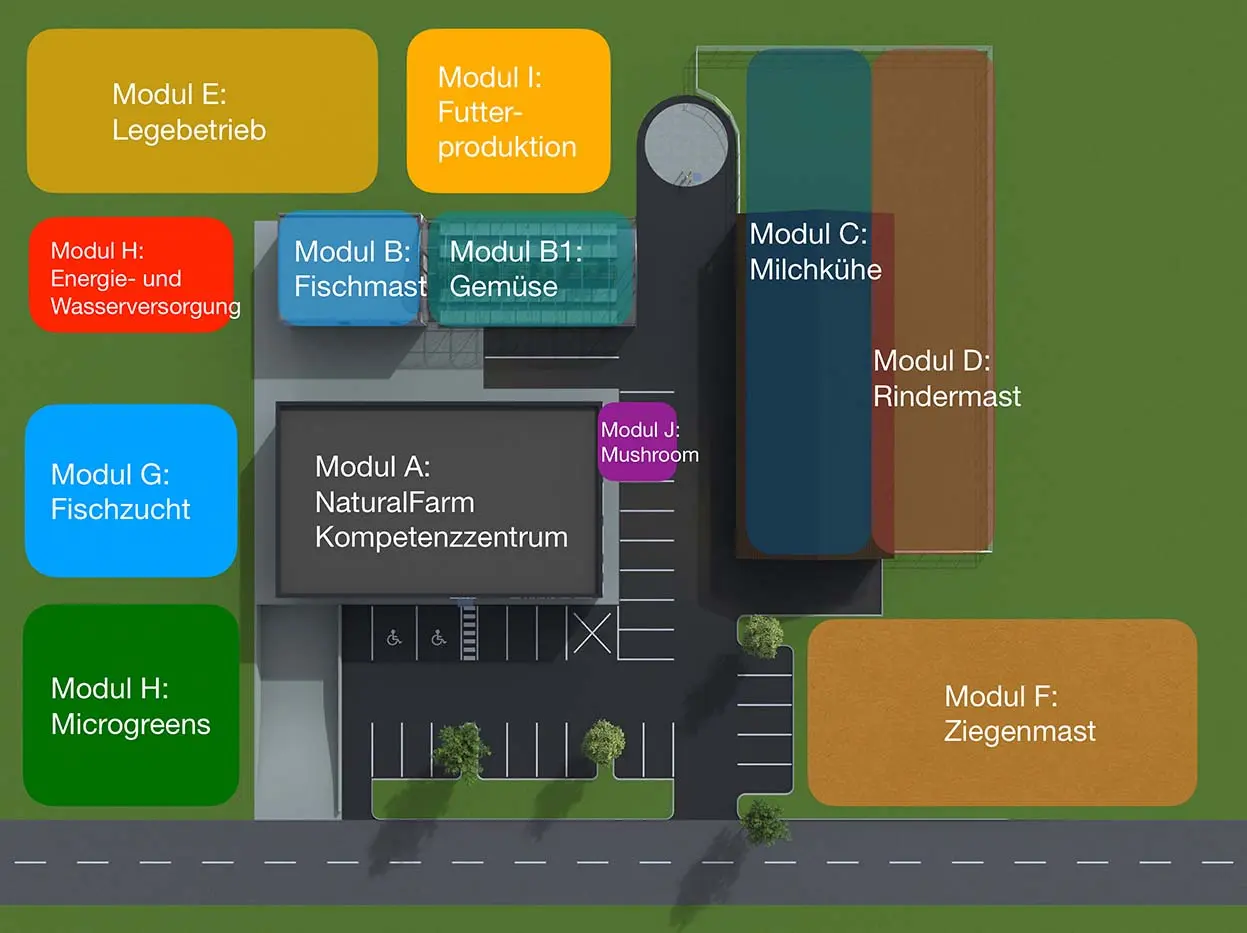

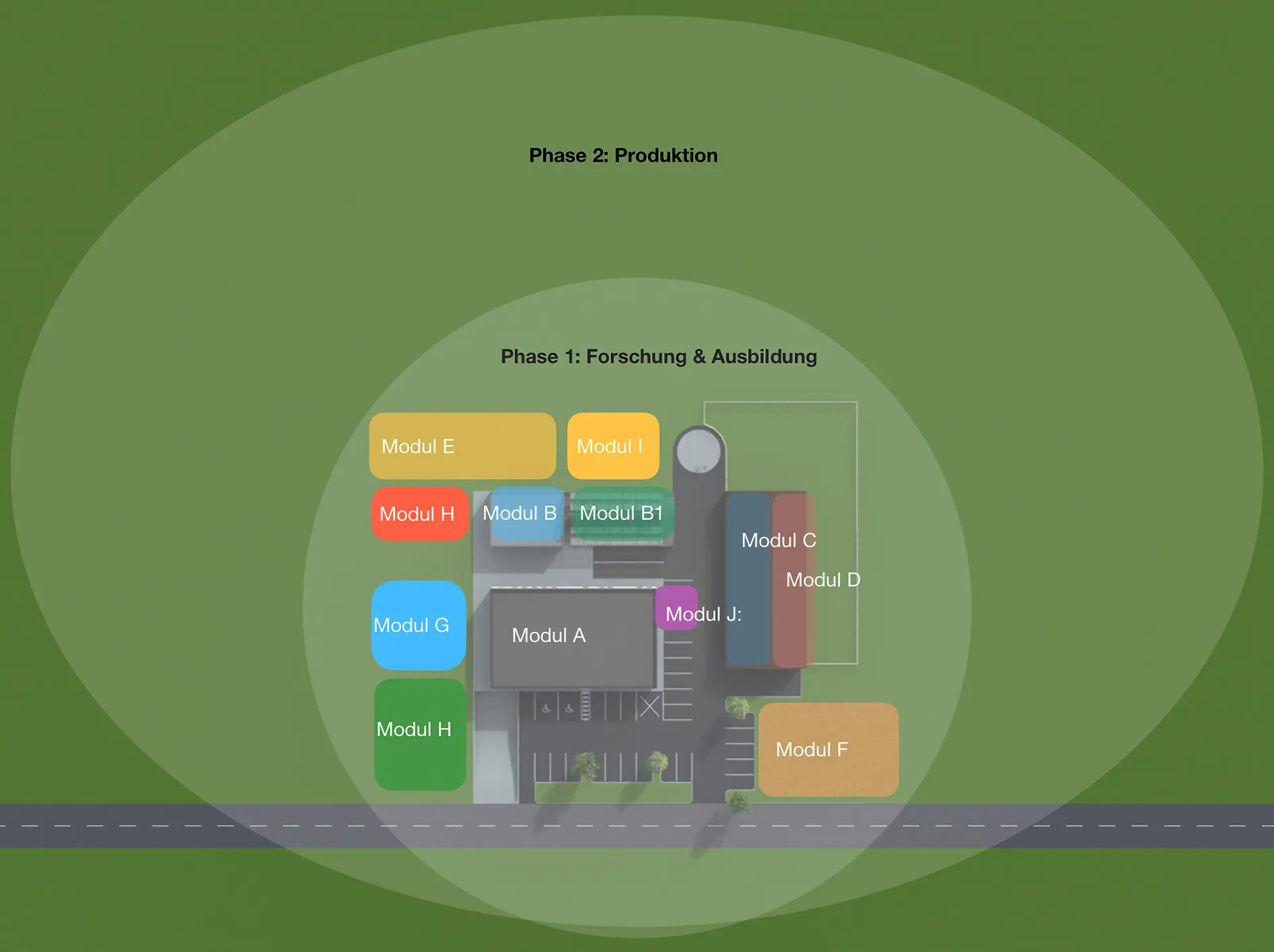

The NaturalFarm Competence Center is a research and training facility that integrates agricultural operations and will later be used for food production. Therefore, the implementation of a NaturalFarm Competence Center occurs in two phases.

Phase 1

Phase 1: Research & education

In Phase 1, various modules are selected, and professionals are trained who will later be involved in food production. These modules include different types of agricultural operations, such as dairy farms or aquaponics systems. The training begins on our farms in Austria, Italy, Liechtenstein, Switzerland, and Germany. The first step involves teaching theoretical foundations, followed by a 1-2 week practical placement to apply the knowledge directly. In the third step, the NaturalFarm Competence Center is established on-site together with us.

Modul A: NaturalFarm Competence Center

Modul B: Fish fattening

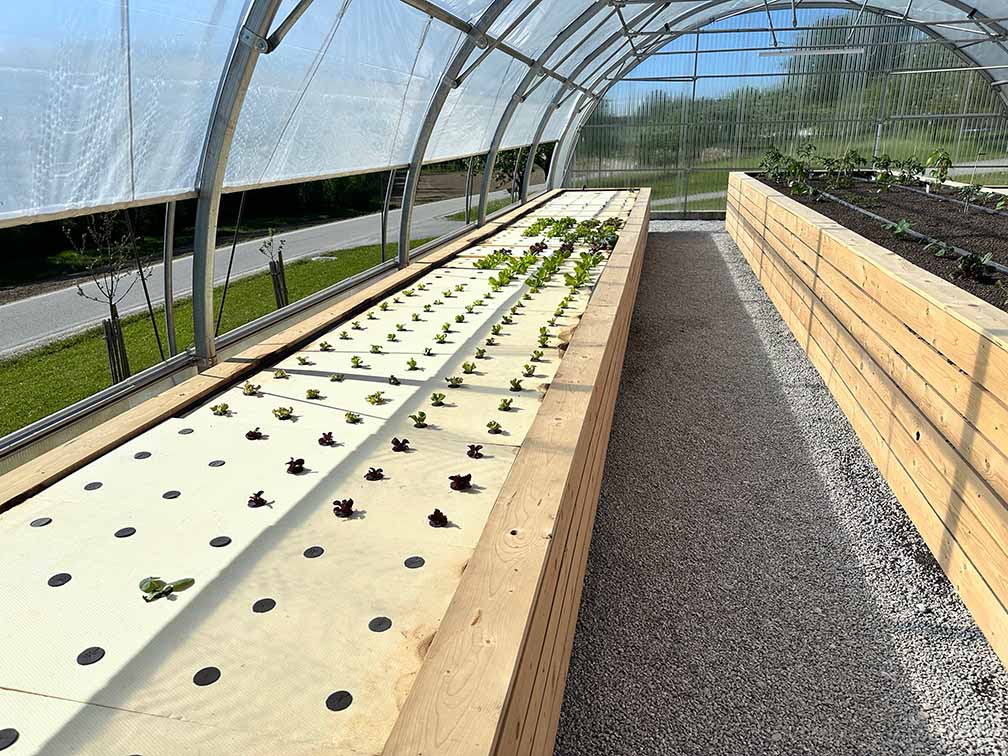

Modul B1: Vegetables

Modul C: Dairy cows

Modul D: Cattle fattening

Modul E: Laying farm

Modul F: Goat fattening

Modul G: Fish farming

Modul H: Microgreens

Modul I: Animal feed production

Modul J: Mushroom cultivation

Modul E: Energy and water supply

Phase 2: Production

Once the center is operational, the acquired knowledge is deepened over a period of 6-12 months, and small-scale food production begins. In Phase 2, larger agricultural operations are expanded to produce the desired quantity of food.

Room layout & equipment

Room layout

Total length: 30.0 m

Total width: 18.0 m

Room height: 4.0 m²

Floor area outside: 540.0 m²

Interior floor area: 482.5 m²

Exterior wall area: 384.0 m²

Interior wall area: 884.8 m²

Interior volume: 1930.0 m

Training rooms

Dairy

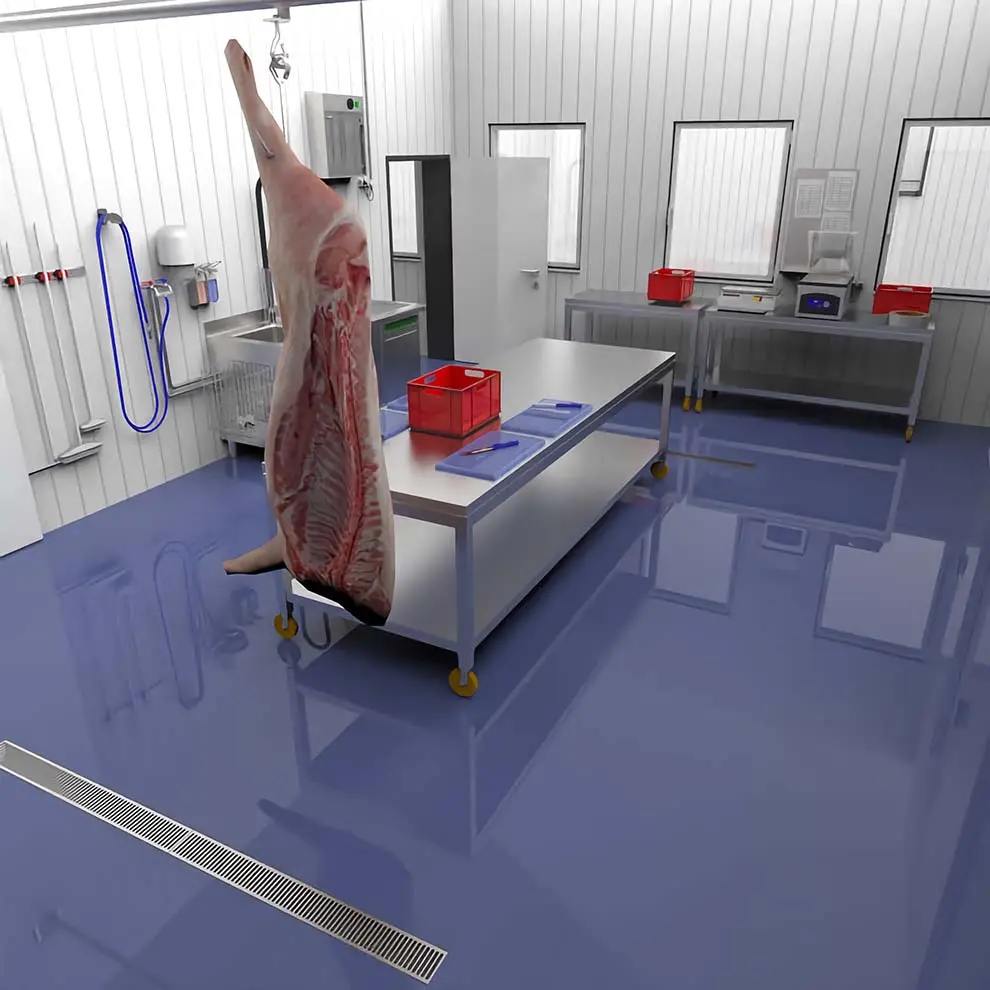

Meat processing & slaughtering

Vegetable preparation

Logistics

Equipment

Investing in a NaturalFarm Competence Center is a safer choice, as it focuses on sustainable and future-oriented agriculture. By training professionals, strengthening local structures, and promoting innovative technologies, a stable foundation for long-term success is established. This reduces risks associated with global supply chains and market volatility, while also offering the flexibility to meet growing demands in food production. This not only increases food security but also enhances the potential for stable and sustainable returns.

Impressions

Aquaponics plant

Plant type: commercial plant

Production type: approx. 25 tonnes / fish per year

Country: Austria

Aquaponics plant

Plant type: commercial plant

Production type: approx. 25 tonnes / fish per year

Country: Austria

Dairy

Plant type: commercial plant

Operating mode: direct distribution

Production type: approx. 200,000 kg / milk and yoghurt per year

Country: Italy

Dairy

Plant type: commercial plant

Operating mode: direct distribution

Production type: approx. 600,000 kg / milk and yoghurt per year

Country: Swizerland

Dairy

Plant type: commercial plant

Operating mode: direct distribution

Production type: approx. 250,000 kg / milk and yoghurt per year

Country: Italy

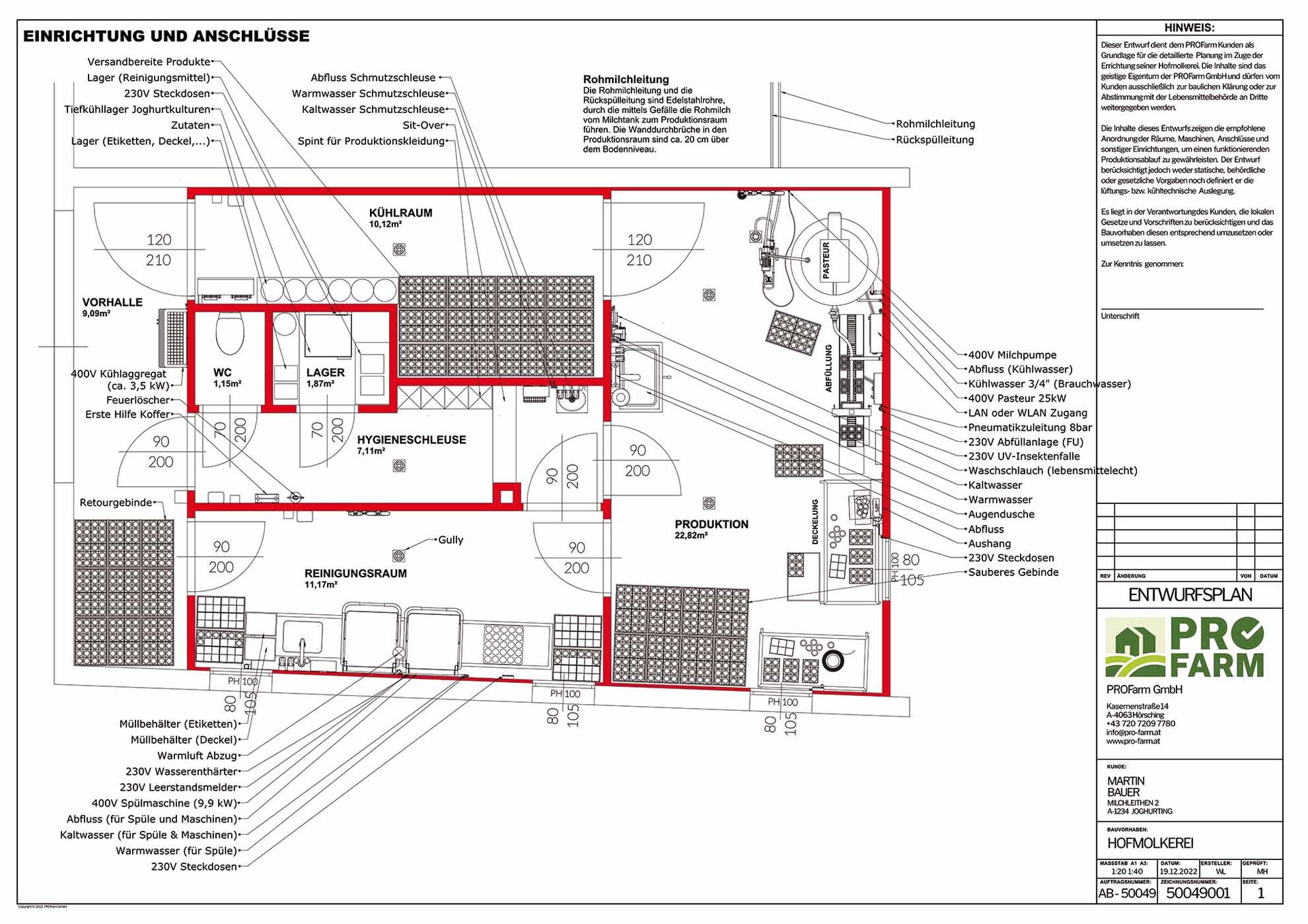

Various state of the art plans

The complexity of comprehensive concept planning for processing rooms is impressively illustrated in the plan shown above. Each individual process is precisely described to ensure that all quality criteria are met to the highest standards.

The complexity of comprehensive concept planning for processing rooms is impressively illustrated in the plan shown above. Each individual process is precisely described to ensure that all quality criteria are met to the highest standards.Your Future Starts Here:

Choose Sustainability and Independence with the NaturalFarm Competence Center.